The National Academy of Engineering recently released the Grand Challenges for Engineering for the 21st century. Among the challenges posed was to restore and improve urban infrastructure. The report noted that urban areas are particularly susceptible to damage from natural disasters, and solutions should be economical so as to be broadly distributed. The January 12, 2010 earthquake in Haiti, and the February 27, 2010 Chile earthquake are stark reminders of the importance of earthquake resistant design. While the earthquake design practices in Haiti and Chile are distinctly different, both countries sustained significant damage to buildings, with estimates of approximately $11 billion for reconstruction in Haiti, and $30 billion in Chile. In both earthquakes, significant damage occurred to reinforced concrete buildings.

The estimated number of vulnerable reinforced concrete (RC) frame buildings in seismic zones in the US, and around the world is staggering, including both developed and industrialized countries. In industrialized countries, such as the United States, thousands of reinforced concrete buildings are considered to be at risk since the building codes did not include adequate seismic detailing requirements prior to the 1970’s. In areas of large, but infrequent events, such as the Central and Southeastern U.S., seismic detailing requirements did not begin taking form until the 1990’s.

INNOVATIVE RETROFIT MEASURES

In this study, innovative retrofit measures using SMAs and other passive technologies are evaluated, at full-scale, using the UCLA mobile shakers. The retrofit of an existing non-ductile concrete building will be used as an illustrative case study. However, the technologies to be demonstrated can be used with other structural systems, and are applicable to both existing and new construction. The innovative retrofit measures that will be studied in this project will result in building systems have the following characteristics in common:

- The retrofitted buildings will have comparable or better performance to traditional retrofit measures use for vulnerable reinforced concrete buildings.

- The retrofit measures will be easily applied (requiring little-to-no heavy machinery), will be scalable and adaptable, and will require little-to-no maintenance during their life span.

- The systems will provide optimal cost-benefit ratios in a life-cycle context.

The novel full-scale field testing, new model development, and complementary life-cycle analysis models will form the foundation for the validation of a new class of retrofits that can be widely applied to a large class of existing reinforced concrete buildings.

VISION & GOALS

The vision of the proposed project is that innovative retrofits will be developed that are easy to apply, cost effective, and can result in significant improvements in building seismic performance. The ease of installation, coupled with performance improvements can significantly enhance community resilience by providing building owners with options that do not currently exist.

This project aims to shift the paradigm in seismic retrofit from one focused on life-safety in major structures to one in which the performance metrics are driven by minimization of damage to smaller structures, including low-rise residential and commercial buildings. The focal point of the project is the full-scale field testing of innovative structural systems which have recentering and/or high energy dissipating capability. These systems are also efficient in their design, passive in nature, require minimal maintenance, and do not require the use of heavy machinery for installation. Close collaboration with several design firms (in Los Angeles, San Francisco, Memphis, and Atlanta) and nitinol shape memory alloy (SMA) manufacturers will ensure the development of practical and cost-effective devices and installation techniques, and will assist in rapid transfer of technology to practice.

KEY PROJECT ACTIVITIES

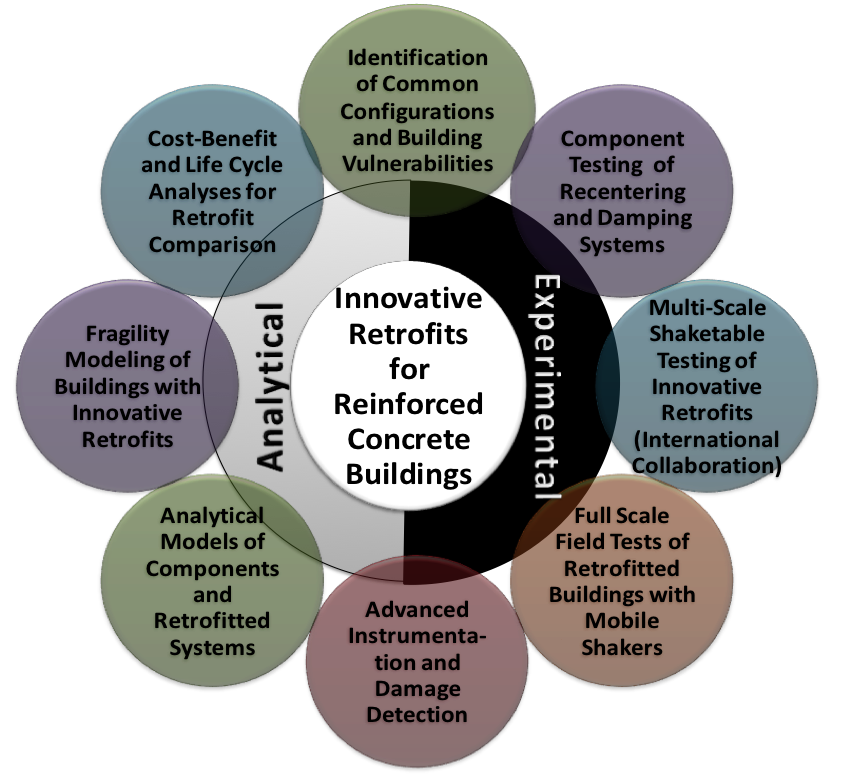

Figure 1 at left presents an overview of key project activities, as well as systems to be evaluated in this study, indicating the highly interrelated experimental and analytical thrusts. The project is divided into 7 tasks:

Figure 1 at left presents an overview of key project activities, as well as systems to be evaluated in this study, indicating the highly interrelated experimental and analytical thrusts. The project is divided into 7 tasks:

Tasks 1 through 4 are focused on the design and experimental aspects of the project, including large-scale component level testing (at Georgia Tech and Hongik University), small-scale system-level testing (Sherbrooke University), and medium-scale shake table testing (National Taiwan University), as well as system level field testing using the NEES @ UCLA equipment (in Atlanta).

Tasks 5 through 7 couple the experimental results of the first four tasks with detailed system-level nonlinear analyses, fragility modeling, and probabilistic cost-benefit studies to develop a framework for decision-making to evaluate high performance retrofit techniques such as those proposed in this project.

COMPONENT TESTING OF RECENTERING AND DAMPING SYSTEMS OVERVIEW

Researchers: Matthew Speicher (NIST), Masahiro Kurata (Kyoto University), Reginald DesRoches (GT), Darel Hodgson (NTI)

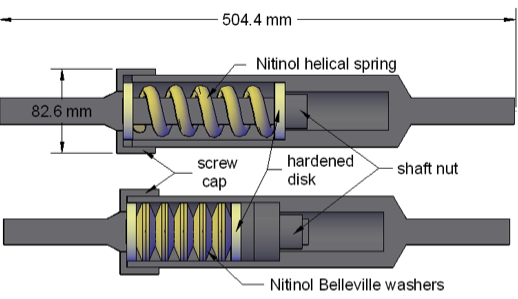

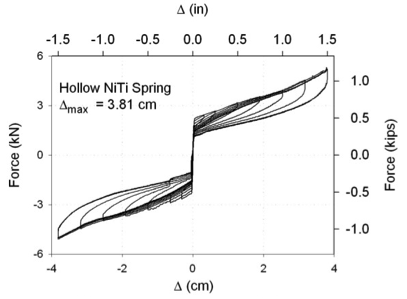

The inherent advantage of using an SMA-based system is that it can be designed to have (1) the ductility and energy dissipation to prevent collapse and (2) the ability to significantly reduce the residual deformations after an earthquake occurs. A tension/compression device is developed for applications as bracing elements in buildings. The device is designed to allow Nitinol forms, such as helical springs or Belleville washers, to be used in compression. The device allows both overall extension (tension) and compression while subjecting the Nitinol to an optimum deformation mode. It is possible, due to the versatility of the design, to adjust the force and stroke of the device without changing the overall configuration. This new device is subjected to a cyclic loading protocol that tests the Nitinol elements ability to recover large deformations. The effect of different Nitinol configurations and a cyclic loading history are evaluated in the study. The results show that Nitinol helical springs produce good recentering and damping behavior while Nitinol Belleville washers show good potential to form the basis for a Nitinol damping device.

Figure 2: SMA Devices (left) Helical Spring and Belleville Washer (right) Force Displacement for Helical Spring

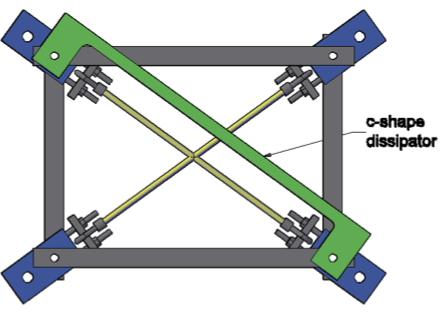

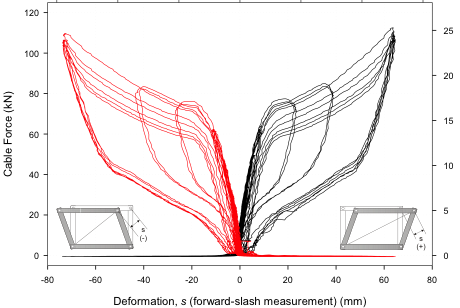

An articulated quadrilateral (AQ) bracing system is developed and tested for seismic resisting applications. The AQ setup provides a convenient means of combining in parallel NiTi wires with energy dissipating elements. For these prototype tests, NiTi SMA wire bundles were combined with long C-shape energy dissipators in an attempt to create a system with a good balance of recentering and energy dissipation. The bracing system maintained good strength, ductility, and recentering after being cycled up to 2% drift. By using the same basic bracing setup, a wide range of force-deformation responses are at an engineer’s disposal by simply varying the geometry of the AQ, cross-sectional area of the NiTi wire bundles, and the dimensions of the C-shape dissipators.

Figure 3: (Left) SMA Based Articulated Quadrilateral (AQ) and (Right) Force Displacement for AQ.

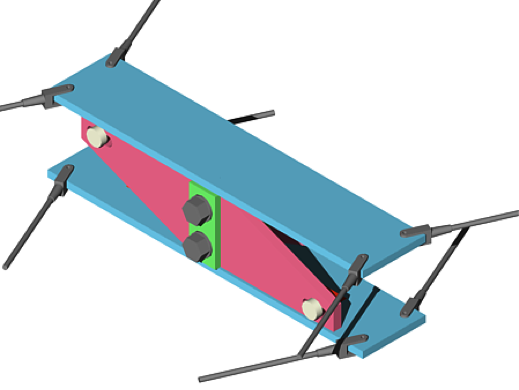

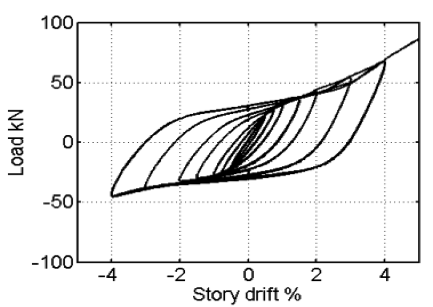

The final device tested is the CORE Damper. The goal of this devices is to design and evaluate simple and rapid seismic retrofit devices for relatively small rehabilitation projects. These designs are consistent with the tenets of sustainable design and will result in a more resilient building stock as well as minimizing environmental and economical impacts and social consequences during the rehabilitation project. To achieve these goals, a unique approach to design supplemental systems using tension-only elements is proposed, one that eliminates undesirable global and local buckling. The first generation of these devices, a bracing system consisting of cables and a central energy dissipating device (CORE Damper), is presented herein. Both analytical studies with advanced and simplified models and proof-of-concept testing demonstrated stable, highly efficient performance of the system under seismic loads. Preliminary applications of the CORE damper system to the retrofitting of a braced steel frame showed the ability of the system to minimize soft story failures as well as residual deformations.

Figure 4: (Left) CORE Damper Configuration and (Right) Force Displacement Relationship.

Select Publications:

- Kurata, M., Leon, T., R., DesRoches, R (2012). “Rapid Seismic Rehabilitation Strategy: Concept and Testing of Cable with Couple Resisting Damper (CORE Damper),” Journal of Structural Engineering, ASCE, Vol 138, No. 3, pp. 354-362, March, 2012.

- Speicher, M., Hodgson, D.E., DesRoches, R., Leon, R. T.(2009) “Shape Memory Alloy Tension/Compression Device for Seismic Retrofit of Buildings,” Journal of Engineering Materials and Performance, Vol. 18, No. 5-6, pp. 746-753, August, 2009.